Barren tundra. Empty forests. Gray November skies drooping over lifeless fields like deep depression. Some hunts are like that. We hike and glass and prowl for miles in a gameless world, frustrated, dejected. This is Nature in all her mystery. Teeming with game one day, barren the next. We must respect her whims, take solace in knowing the sun will shine again. Elk will bugle, whitetails wander and pronghorns parade. With that hope to sustain us, we trudge on, leaden steps under leaden skies, but not necessarily with leaden bullets.

I apologize for my pathetic poetic introduction to a decidedly prosaic subject: lead versus copper bullets. The two metals find themselves embroiled in a battle for hunting supremacy. Lead, long the standard for hunting projectiles, has enjoyed more than a century of evolution and advanced development. From round balls to patched balls to conicals, hardened lead, copper and gilding metal jackets, tapered jackets, hollow points, flat points, bronze tips, polymer tips, partitioned jackets, bonded cores and hollow copper noses backed by tungsten cores. We’ve tried every trick to perfect the basic lead bullet. It was inevitable that someone would get the lead out entirely, and that someone was Randy Brooks, creator of the Barnes X-Bullet way back in 1988.

The X faced plenty of headwind fueled by equal parts bias and tradition. Inaccurate. Barrel fouling. Excessive pressure. No expansion. Despite it all, the X soldiered on, evolving, steadily gaining converts. And eventually imitations and competitors. Today there are at least 20 different manufacturers of copper alloy bullets.

When Elizabeth Spomer applied a 150-grain copper Hammer bullet from a 300 H&H to the chest of this common reedbuck, it collapsed instantly, suggesting expansion was not an issue.

It isn’t exactly monometal mania, but competition in the non-leaded bullet business is heating up, the threat of government lead bullet prohibitions fueling development. While many interpret lead bullet bans as the latest tactic of anti-hunting forces, there are stacks of evidence proving a direct lead-to-dead connection. Lead toxicosis has been documented most infamously in California condors, but also bald eagles, golden eagles, loons, swans and crows. Of course, ducks and geese were the first harbingers of the lead poisoning problem, millions of them dying after eating spent shot at Horicon Marsh in Wisconsin, and in hundreds of other waterfowl hunting hot spots around the country. Lead shot for waterfowl hunting was outlawed in 1992. Lead was banned in paint in 1977, gasoline in 1996. The inevitable seems inevitable.

I’m not advocating any kind of government ban on lead-core bullets. Not for hunting, not for target shooting, not for self defense. I’m merely making an informed decision of my own and celebrating the impressive performance of today’s monolithic, copper alloy bullets.

Today’s lead-free copper hunting projectiles flat out work.

And by “work” I reference terminal performance, ballistic performance, accuracy, reduced in-barrel friction, higher velocities and decreased recoil. There’s just a lot to like about a good copper bullet.

Large cartridges such as this 458 Lott are not supposed to be particularly accurate with any bullet, let alone an all copper model, yet 500-grain Barnes Vor-TX ammo punched this group from 100 yards.

Here’s the deal. Copper has a lower specific gravity than lead. Make two bullets of the same diameter and shape, one with a lead core under a copper or gilding metal jacket, the other out of a pure copper alloy, and the lead core will weigh more. That means it will have a higher Ballistic Coefficient because mass is one leg of the B.C. triad, the other two being diameter (the narrower the better) and form factor (the sleeker the better.)

B.C. is all the rage these days because the higher it is, the more aerodynamically efficient your bullet is. That means it shoots flatter for a given muzzle velocity, deflects less in crosswinds and retains more energy at all distances. Win-win-win.

Hammer’s 270-grain Shock Hammer copper alloy bullets in .375 incorporate a double radius relief groove system that minimizes bore contact. The hollow nose is engineered to break away, scattering petals while leaving a “square front” to radiate energy 90-degrees from the main wound channel. The spent bullet was recovered against the offside hide of a chest-shot Cape buffalo.

To equal the B.C. of its lead-core competition, an all-copper must be made longer, long enough to equal the mass of the lead core. EZ PZ except…that often makes the heaviest bullets for caliber too long to stabilize in traditional twist barrels. Your old 270 Win., 30-06, 243 Win., etc. could be throwing wobblers. You’d need a new barrel with a faster twist rate like one complete revolution in eight inches of barrel instead of one in ten inches. Or just shoot the shorter, lighter weight coppers.

Fortunately, Nature engineered a cool compensating feature for copper. Much the way a light heavyweight boxer can make up for smaller fists by adding speed to his punches, a lighter copper can make up for mass with higher muzzle velocity. A full case of powder will drive a lighter bullet faster than a heavier one. Given reasonably decent form, the faster one will shoot flatter at all sensible hunting distances and often to 1,000 yards. The longer, higher B.C. option, however, deflects less in crosswinds. That’s the biggest trade off.

Faster muzzle velocity with the shorter copper projectiles is effective because another attribute of copper is mass retention. While a lead core bullet—even the bonded, partitioned styles—loses mass via lead breakup or simple erosion against hair, hide, muscle and bone, a monometal copper bullet does not. Fire a 180-grain copper through a grizzly, find it in the snowbank beyond, and chances are it will still weigh 180 grains. Lead core 180s might end their journey weighing 20- to 50-percent less.

Barnes copper bullets in their various configurations have been deep penetrators and consistent killers for Spomer in a wide selection of calibers and cartridges from .224 through .458.

Some hunters prefer their bullets lose weight and remain in the target so all energy is used to kill it. I suspect that’s a flawed concept. I could be wrong, but look at it this way: If a particular bullet hits your elk carrying 2,000 foot-pounds of energy, mushrooms to 1.5 times its original diameter, busts through the shoulder, tears the top of the heart and the lungs, breaks an offside rib, then stops against the hide on the far side, that elk will have absorbed 2,000 foot-pounds of tissue destroying energy. Never mind that most of that energy will be absorbed by tissue elasticity with minimal permanent damage beyond what the bullet actually touched, cut, ripped and shredded. Let’s just assume all 2,000 pounds of kinetic did effective work.

Now, along comes an all-copper bullet carrying 2,500 foot-pounds of energy. Same strike, same expansion, same ripping and tearing, but it punches right through. It still required 2,000 foot-pounds of energy to do its work and reach the offside hide, so…did it not do the same amount of damage, dump the same foot-pounds of energy? The extra 500 foot-pounds it used to punch out and hit the hillside don’t matter except they leave a second hole, usually a substantial one, for enhanced blood trailing.

If this theory sounds flawed, we might shed more light on the situation by considering what traditional bullet makers have been striving to perfect over the past 150 years or so. Based on every advertising photo I’ve ever seen, the ideal bullet is either the classic Remington “Most Deadly Mushroom in the Woods” or the “exploded” shrapnel of a classic varmint bullet. The mushroom is considered best for big game. But expansion isn’t the only desired outcome. Behind that dramatically expanded nose should be a sizable shank with enough mass to drive the broad nose forward. Expansion and penetration. The deadly duo.

Well designed copper bullets mushroom like lead core bullets, but lose virtually no mass while retaining long shanks for maintaining momentum. Note how these bonded lead core bullets (right three) have lost lead to erosion.

Achieving this with lead cores has long been the challenge. At high velocities the core and jacket separate, and penetration is compromised. Additionally, lead often breaks into two or more pieces, sometimes hundreds of tiny flecks. This is why John Nosler created his Partition bullet. The lead nose is free to mushroom, erode and break up, but the locked-in shank lead keeps driving. The Swift A-Frame amplifies that concept with a thicker jacket and wall plus nose lead molecularly bonded to the copper jacket. Other bullet makers skip the wall and bond the entire lead core to the jacket. Some bond lead in the nose and leave the shank a solid rod of copper alloy. Some make the nose hollow copper alloy and fill the shank with lead. There are several variations on this theme, all of them designed to strike the perfect balance between expansion and weight retention for maximizing tissue destruction and penetration.

Bullet makers have tried every design imaginable to perfect terminal performance of lead core bullets. Thick jackets, partitions, simple cup-core lead insertions, tapered jackets with extra thick bases and bonded lead cores, and dual hardness lead cores.

When considering copper bullets, we should keep that goal in mind. Game doesn’t care if it’s struck by lead, steel, copper, tungsten, oak or gold. Regardless the material, if it expands to rip vital tissue and retains sufficient mass, thus momentum, to penetrate all viral organs, it maximizes terminal performance.

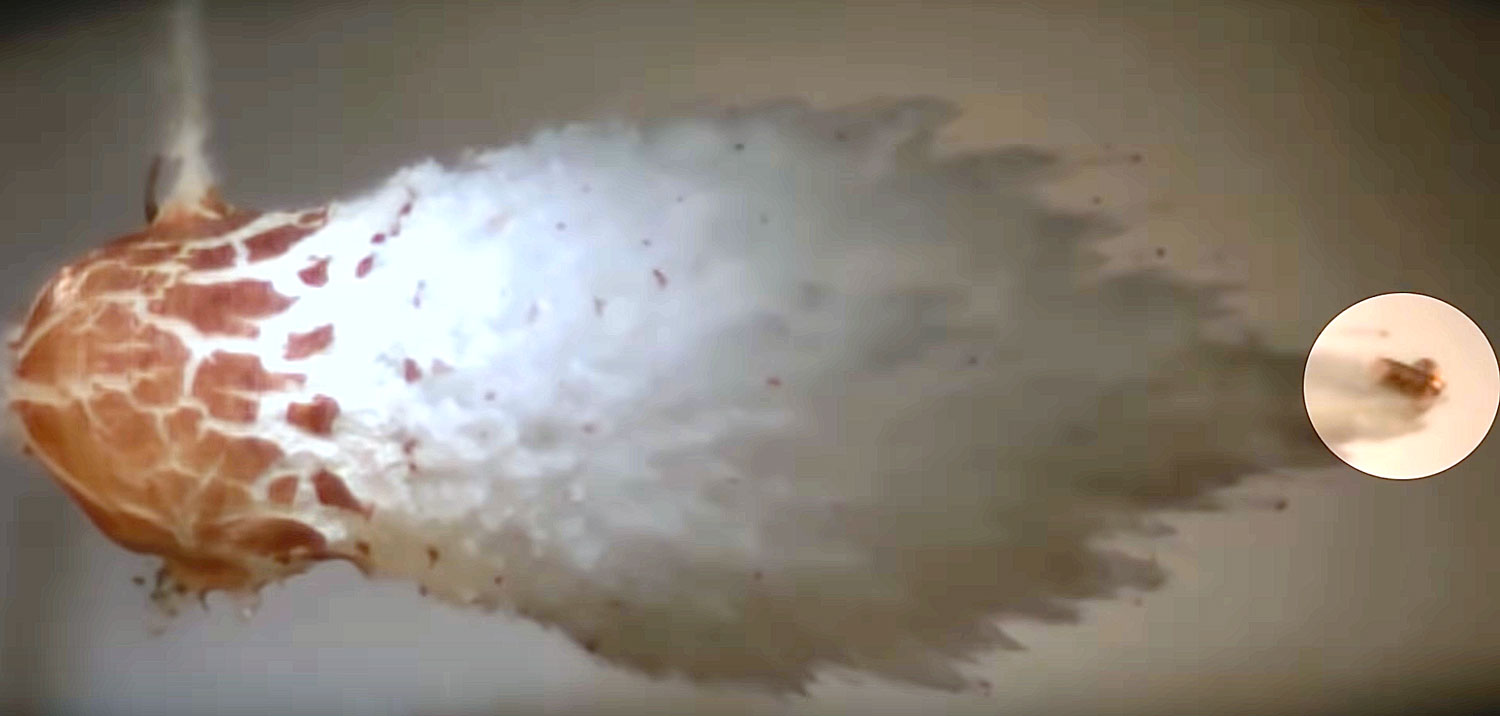

A single frame capture of a slow-motion video from Barnes Bullets shows a TSX fully expanded after exiting an apple.

Copper bullets do this in one of two ways. A hollow cavity in the nose is blown open by the hydraulic pressure created when fluid body tissue enters the hollow of a projectile moving 1,000 to 2,000 miles per hour (roughly 1,500 to 3,000 fps.) Surrounding copper, often internally scored, flares out and curls back during contact with tissue, twisting under the friction of spinning 150,000 to 280,000 revolutions per minute. Sometimes petals break off during contact with bone. Little or no copper erodes away. Alternatively, the nose hollow is designed so that petals shear off, the pieces diverging from the main bullet path to cut and tear additional tissue. Meanwhile, the flat, leading surface of the remaining shank radiates energy 90-degrees from that surface, theoretically tearing tissue via fluid transfer.

Thirty-five years of real-world testing by thousands of hunters targeting everything from dik dik to dinosaurs (crocodiles) have cemented the efficacy of the best copper bullets, so now more and more designers are entering the market. Efficient designs include relief grooves, double radius relief grooves, bore riders, driving bands and many of the same polymer and bronze tips as seen on lead core bullets. Because copper bullets are uniformly dense and lathe turned to extremely tight tolerances, they are typically perfectly balanced for fine flight characteristics and accuracy.

A bushbuck, even an old ram like this, is no thick, massive heavyweight, yet this one fell within 10 yards after being chest shot with a 124-grain Hammer Hunter copper bullet. Clearly, terminal performance was adequate.

In my experience, any questions about copper bullet performance have been answered and answered emphatically. The best of them work as well as if not better than most lead core bullets. It is now a tight race. You might want to enter it.

I do not believe governments should mandate their use (except in critically endangered California condor range) for three reasons.

1. Spent lead bullets have not and are not jeopardizing populations. Bald eagles, for instance, have been increasing in numbers dramatically since DDT was banned in 1972. They routinely feed on hunter-killed deer and elk gut piles. Similarly, I’ve seen no evidence that turkey vulture, crow or raven numbers are declining.

2. Government restrictions/mandates create resistance. Many hunters who might switch to copper for performance advantages would intentionally refuse to use them just to thumb their noses at government overreach.

3. Prohibitions rarely work. It’s been against the law to litter since the 1960s, but that problem hasn’t gone away.

There are some reasonable arguments for and against a lead bullet ban. You can read about some below:

Why a Lead Bullet Ban is a Bad Idea or Unnecessary

Would create instant resistance on the general principle of government overreach.

Ammunition loaded with copper bullets can be hard to find and expensive, especially in older cartridges such as 35 Remington, 250 Savage, etc.

Some rifles refuse to shoot any copper bullet accurately, although this is rare.

Lead bullets have been used for hundreds of years without evidence of poisoning in humans, coyotes, wolves, bears, badgers, foxes or other mammalian scavengers. In fact, most carnivorous mammals have been increasing in numbers and distribution. So have humans.

Twenty-five years after DDT was outlawed in 1972, bald eagle populations in the Lower 48 increased from 417 nesting pairs to more than 5,000 despite scavenging big game carcasses killed with lead core bullets.

Why Switching to Copper is a Good Idea

Ballistic and terminal performance can be outstanding.

There is extensive and compelling scientific evidence that lead from hunting bullets has been and is poisoning endangered California condors, golden eagles, bald eagles and many other scavengers. Leaving lead fragments and smears in gut piles, boned carcasses and unrecovered game ends up poisoning some scavengers that eat it. Even if these are too few to impact overall populations, do “conservation hunters” want to be responsible for needlessly poisoning non-target animals?

Voluntary use of non-toxic bullets is a good public relations move. Anti-hunters can more easily win over non-hunters if they can point to hunters’ callous indifference. Knowingly and willfully shooting bullets known to poison scavengers, especially our white-headed national symbol, is not a winning PR move.

Are we absolutely sure that lead in meat, whether tiny fragments or mere smears, is not harming our kids and grandkids?